Top 8 Reasons Why Maintenance Training Improves Facility Safety

Written by Staff Writer

Here's our list of the top reasons your entire team should be attending the same maintenance training. Did we forget anything? Let us know in the comments!

8. Standardizes best practices

Training courses allow workers to learn the best practices for their jobs, whether it be safety precautions, troubleshooting methods, or simply tricks of the trade. When multiple workers participate in training as a team, they can rally around the best practices learned in their training courses. That way, if one worker starts a process using a standard procedure that the whole team understands, anyone from the team can finish it safely and effectively. With the staffing difficulties many facilities are experiencing with maintenance worker staffing shortages at an all-time high, being able to reliably pick up where a previous worker left off not only ensures that the procedure will be done safely, but also saves time figuring out if any steps were missed.

7. Gives awareness of potential hazards and how to avoid them

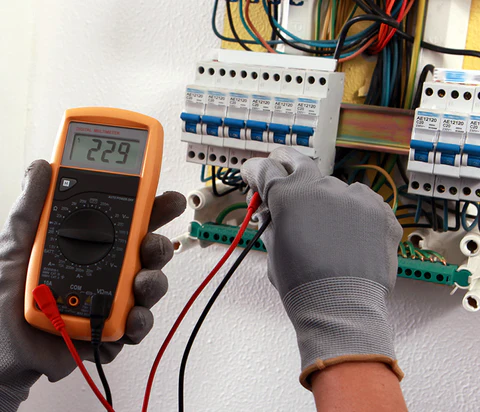

With proper training comes a knowledge of any hazards that workers could encounter doing either routine maintenance or completing repairs. For example, when Lockout/Tagout procedures are followed properly, there is no chance that a coworker will be able to restart a machine or electrical circuit prematurely. Training programs not only cover how to protect yourself from hazards, but why each precaution is important. This type of awareness helps workers avoid injuries from electrical shock, arc flash, and arc blast — not only for themselves but for their coworkers.

When your whole team completes the same training, everyone understands why certain safety precautions are followed. Increasing buy-in to a process or procedure naturally helps to avoid hazards.

6. Provides strong familiarity with national safety standards

A solid training background builds a foundation in safety standards, which are put in place to improve workplace safety. It isn’t just those with electrical licenses who need to understand the national safety standard behind a process. Navigating the national standard gives insight into the requirements and parameters for a safe working environment. Workers with experience navigating a standard can utilize their familiarity to start a conversation with their colleagues about how to improve safety in their facilities. Some of the standards that will be helpful for your maintenance workers to be familiar with are: NFPA 70E Standard for Electrical Safety in the Workplace, OSHA CFR 1910, and NFPA 70 National Electrical Code.

5. Reduces faulty repairs

Human negligence is one of the top reasons for industrial accidents. By requiring your workers complete maintenance, electrical, and safety training, you can prevent most major accidents from ever happening. After completing training, workers will understand how to properly complete a repair and when to escalate a repair to a licensed member of a skilled trade.

4. Preventive maintenance, when done properly, is worth its weight in gold

“Preventive maintenance training can save organizations lots of money in the long run, through significantly less downtime, safer and more efficient machine operation, and instilling a culture of career advancement and skills growth within departments that retains the top talent.” – Ryan Smith, Enterprise Content Manager and one of the instructors at TPC Training.

3. Keeps knowledge up to date

Safety standards are constantly evolving. Each 3-year code cycle, the industry discovers new and innovative ways of keeping workers safe on the job and documenting those best practices in national codes and standards. If your employee is new to the company or role, their training might be out of date or incomplete. By keeping training current, electrical and maintenance workers not only protect everyone else in the facility, but also prevent many safety problems from happening in the first place.

2. Promotes safety through improved efficiency

The better a system runs, the less likely you are to have faults or other problems or major maintenance/shutdown in the future. The key to keeping machinery running efficiently regardless of its age is preventive maintenance done at the recommended intervals and, when necessary, repairs completed correctly and in a timely manner by properly trained maintenance staff members.

1. Allows for hands-on practice — the best tool in the training arsenal

This is our top pick for improving safety. When training includes hands-on practice, your employees benefit in many ways. Here are a few things that they’ll learn from instructor-led training:

- Building skills through practice on real equipment

- Knowing how to troubleshoot safely

- Developing confidence in their skills

- Instilling employer confidence in employees

- Utilizing detailed simulations that allow workers to make mistakes in a safe environment without causing arc-flash or fire.

What other benefits has your team reaped from attending maintenance training?

TPC offers over 1,000 online course hours including the technical skills your teams need in order to impact workplace safety. Check out our full catalog!

Learn about instructor-led seminars offered by TPC Training.

Already love our courses? Here’s where you can purchase training blocks to save over purchasing individual courses.